Small changes are helping to make a big impact on waste as Dezignatek and its parent company NZ Panels Group work towards a sustainability target of becoming carbon-negative.

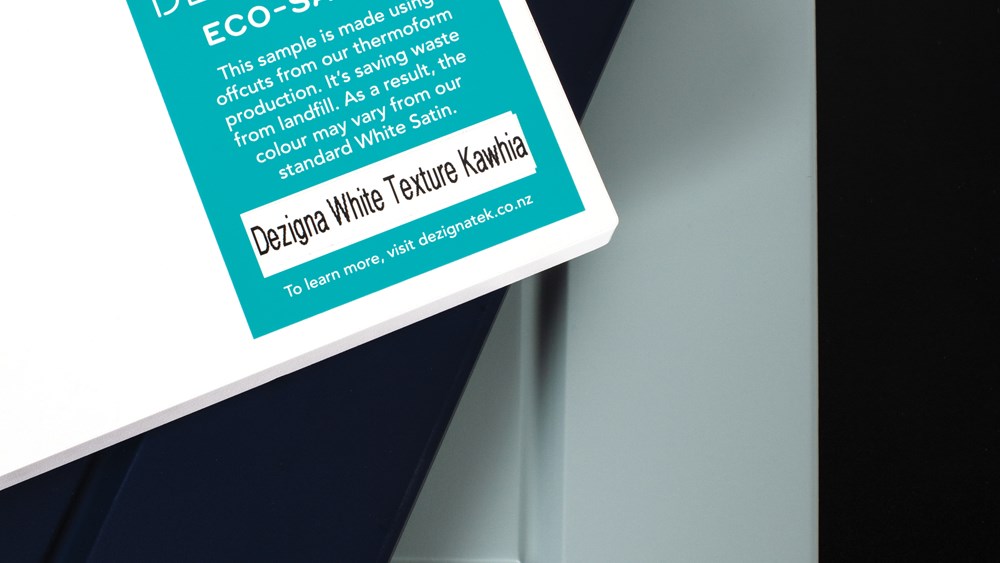

Dezignatek is reducing waste in its production area by making door samples using spare vinyl space on its thermoform presses when it makes client orders. They've also swapped their plastic wrapping for one made from sugar cane.

While the door sample may now vary from the standard Satin White, depending what is on the press at the time, designers and joiners will receive the exact door profile they need and can use a colour chip to help match with other decor surfaces or interior finishes. Any waste vinyl left over from pressing is sent off to be recycled into gumboots, hoses mudflaps and plumbing pipes.

Colour samples are available in chip form and can be ordered via the website at no charge to anyone. Given the size and cost of door samples, these are only made available to designers and joiners. Thermoformed A5 colour blocks are also available on top selling or newer colours.

Another project on our sustainability list has been to swap out the plastic wrap used across the site for a more environmentally friendly option. This type of wrap is needed to protect door panels from the elements but Dezignatek is now using Purewrap made from sugar cane which is carbon positive - removing 2.80 tonnes of CO2 per ton. By comparison, plastic emits 1.66 tonnes of CO2. Handily, it can also be recycled with other soft plastics.